STAGE 5: REVIEW

The final stage of the TQ process comprises an assessment of whether the qualification activities have been implemented as planned, and hence whether the collated evidence satisfies all of the acceptance criteria defined in the TQ plan. According to DNV-RP-A203 a third party can be assigned to:

-

Assess the relevance and completeness of the Technology Qualification Programme and the activities in the Technology Qualification Plan;

-

Review and perform independent analyses and tests to verify the validity of the qualification evidence and conclusions;

-

Confirm compliance with specified standards.

Viewed collectively, the outputs of the qualification activities should demonstrate that the TQ goals have been achieved and provide an overall picture of the actual development stage reached. To facilitate the assessment, the evidence will be documented in a logical and coherent way, demonstrating that the TQ activities have been carried out in a systematic manner. For example, in the case of a quantitative assessment of technology reliability, performance data, (which could be taken from many hundreds or thousands of tests) would need to be fully traceable (i.e., test conditions, sample identifiers etc.).

MANAGEMENT OF CHANGE

|

The qualification activities may reveal opportunities for design improvements to be made, either resulting from identified design shortcomings or residual risks. The motivation for carrying out design modifications could be to:

Significant design changes made to a particular element are likely to lead to a reduction in the TML of the element necessitating remedial measures to be carried out, such as further re-qualification activities, as shown in the flowchart on the left. Furthermore, such modifications may have an impact on the performance of interfacing components and/or subsystems, possibly even necessitating re-qualification of these associated systems, e.g., adjustment of risk assessment scores, further testing and analysis. It is therefore prudent to ensure that the proposed design changes do not result in unacceptable risks. The ABS Guidance Notes on Qualifying New Technologies outlines a Hierarchy of Risk Control Measures methodology to efficiently design-out (or mitigate against) hazards and a means of carrying out the Management of Change (MoC). |

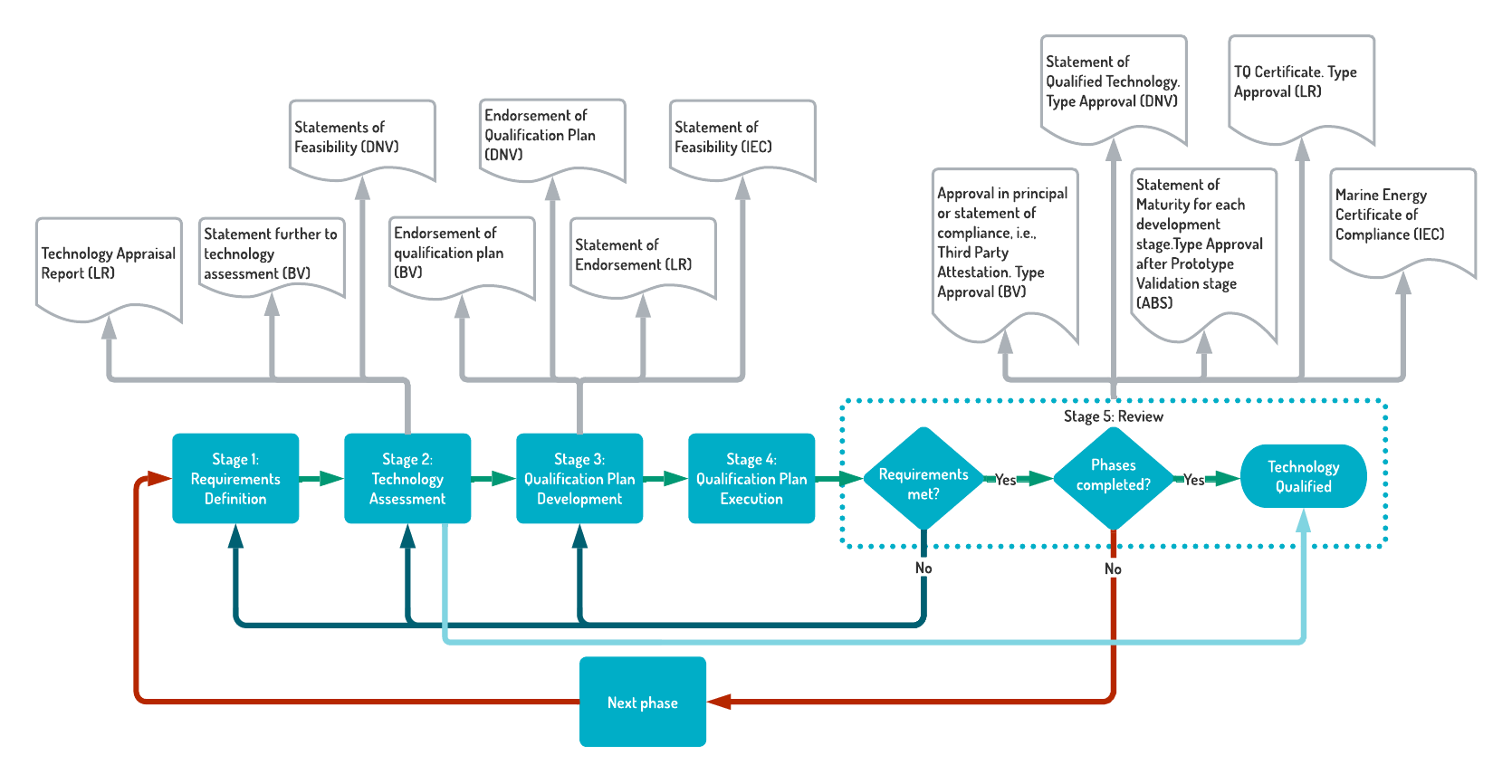

CERTIFICATES AND STATEMENTS

Maturity, risk and overall TQ progress can be reviewed in any of the TQ stages to make sure that the activities are on track. Formal reviews are typically carried out by the Classification Society or other independent third-party. For example, several Societies can endorse the TQ plan following review of the activities in Stage 3, “BV will issue an endorsement of the TQ plan”. Following successful completion of TQ activities and verification of all reports and evidence, ABS will issue a Statement of Maturity, allowing the developer to be able to proceed to the next development stage. A common end goal for technology developers is Type Approval of their product following successful completion of TQ activities. The certification awarded at the end of the TQ process may have a particular period of validity. For example, a Lloyds Register TQ Certificate is valid for 4 years, although this period can be extended, if appropriate, following a subsequent review carried out by the Classification Society. A high-level view of the TQ process, including example statements and certification is shown in the diagram below.

In order to facilitate the oversight of qualification progress, the TQR spreadsheet includes a means of tracking the status of each TQ activity in terms of its relationship to the overall requirements of the TQ programme.